Trusted company that deals in quality-made products

Expert Engineers

We have technical experts to exmaine our products.Quality Work

We deal in providing quality products to our clients.Customer Support

We provide 24/7 support related to any product enquiries.Low Cost

All our products are available at competitive rates.PRODUCTS WE OFFER

Our Products

Why Choose Us!!!

On time delivery

Ensure punctual delivery of melamine products to meet customer expectations and maintain supply chain efficiency.Stable Quality

Consistent, reliable quality assurance for melamine products, ensuring stability and performance in various applications.Advanced color mathching

Utilize spectrophotometry and specialized software to achieve precise melamine color matching for enhanced product quality and consistency.

About

Pristine Melamine LLP

Procure a MFMC and Glazing Powder of Unequalled Quality which is accurately composed and has significantly high properties

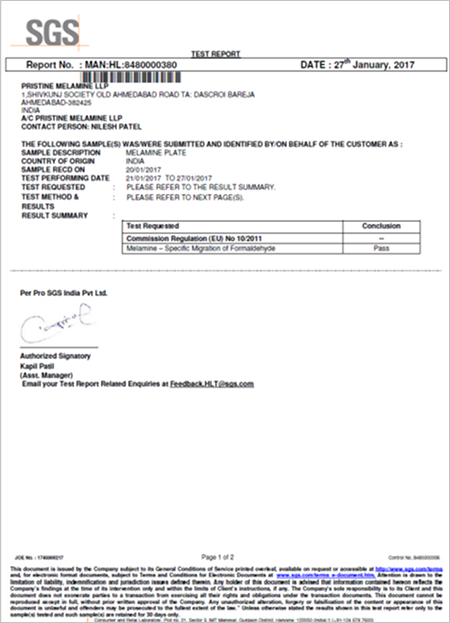

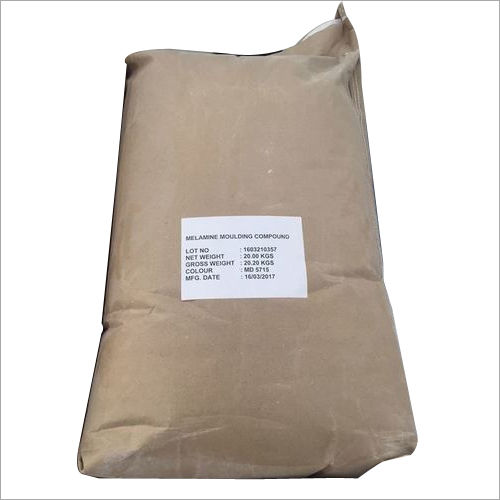

Moulding Compound offered by us is a food grade material mandated by SGS Chemical laboratory, it also meets the hygienic standards for all melamine formaldehyde products such as melamine Molding Compound, Melamine Molding Powder that are used as food containers and boxes.

Don't hesitate to contact us for more information about Pristine Melamine LLP

Our Certifications

Call Me Free

Call Me Free