|

About Us

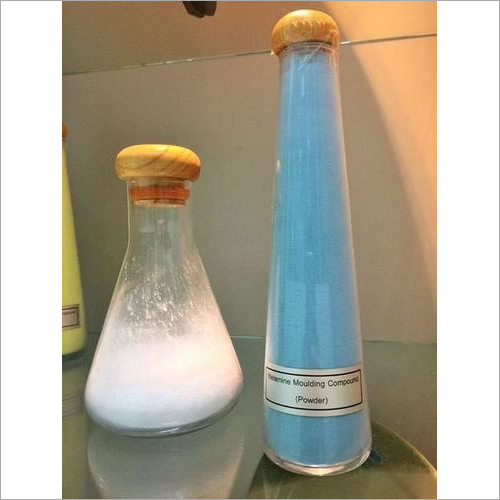

Established in 2016, Pristine Melamine LLP is an ISO 9001:2015 accredited company based in India. Pristine Melamine LLP is engaged in the manufacturing of Melamine Molding Compound, Melamine Molding Powder and Glazing Powder through the implementation of the latest technology and equipment.

Moulding Compound offered by us is a food grade material mandated by SGS Chemical laboratory, it also meets the hygienic standards for all melamine formaldehyde products such as melamine Molding Compound, Melamine Molding Powder that are used as food containers and boxes. Our Abrasive grade Melamine Molding Compound is widely used in manufacturing Diamond Polishing Pads and Granite stone polishing tools.

We have been working to develop mutually beneficial relationships with our clients and it is our main objective to ensure client satisfaction.

What is Melamine?

Formerly

known as Melamine Formaldehyde or Melamine Resin, Melamine can be

categorized as thermoset plastic with ehat resistant and hardness

attributes that distinguishes it from PVC, PP or other thermoplastics.

These characteristics make it an appealing material for variety of

product applications such as household products (tableware and sanitary

ware), industrial products (fire retardant materials, Formica, filters),

electrical components and parts (light switches and socket boxes) and

agricultural inputs (fertilizer).

Melamine

was first synthesized in 1834 in Germany and it was in the 40s that it

was used in commercial applications. A similar polymer, Urea

Formaldehyde was discovered in the 60s and was synthesized at a lower

cost as compared to melamine and proved to be beneficial for its

properties like low density and imparting light weight to finished

products. Unique characteristics of both UF and MF make these suitable

for variety of products, MF is typically used for products which are

subjected to high levels of heat like coffee mugs, plates, soup dishes

etc, while UF is for all kinds of hard plastic products like toilet

seats, trays and more.

At present, China is counted amongst the largest manufacturers of MF and UF compounds.

What is the difference between MF and UF?

An

organic compound, Melamine is used in combination with formaldehyde to

develop melamine resin, a synthetic polymer which is resistant to heat

and fire. Melamine is a versatile item having a stable structure which

can be easily molded into any shape when warm and will set into a fixed

form, making it appropriate for specific industrial applications but

difficult for recycling. Although it can withstand fire and heat as

against other plastics, when exposed to enough heat, it will melt

therefore it is recommended to not expose dishware to high temperatures

like in an oven or micro wave. Melamine is used in floor tiles,

whiteboards, fire retardant fabrics, commercial filters and kitchenware.

UF

resin is an opaque thermoset resin which is obtained by heating

formaldehyde and urea in pyridine or ammonia solution. It is available

in spray dried powder or viscous liquid that demands addition of water

before application. This resin is used as a molding component or

material of protective finishes and adhesives or as a binding agent in

fire board industry. It possesses flexibility, high tensile strength and

heat distortion resistance and forms a resilient finish, when cured.

These attributes have mad this polymer a highly useful and demanded

additive for a wide range of products like binding agents, wood finishes

or adhesives. It is also used in various household products like

tableware, kitchenware, electrical accessories, sanitary ware, finishing

products etc. although it is widely used in various areas, the biggest

disadvantage of this resin is the release of formaldehyde gas in certain

conditions.

Usually

formaldehyde resins are scratch resistant and tough polymers which

makes them apt for both industrial and domestic applications.

Key Features of Melamine Tableware

- Break-resistant as compared to ceramic, glass, porcelain based products, items made of Melamine can withstand rough handling and occasional falls

- Easy to clean and maintain

- Easy to handle low breakage during loading/unloading or transportation

- Lighter than glass based and ceramic tableware

- Clean shiny and seamless finish

- Customizable at manufacturing level in terms of designs

- Cannot be used in the microwave or oven. Some heavier items like kiloy plates can be placed in the microwave for maximum 1 minute

- Scratch resistance and not affected by sharp or dense objects made from metal or glass

Key Features of Melamine Sanitary-Ware

- Better hygiene levels (standards) as compared to plastic or MDF toilet seats because of low porosity

- Stronger than plastic as well as MDF because of its high tensile strength

- Lighter than MDF

- Easy to clean and maintain

- Heat tolerant as well as fire resistant

|

PRISTINE MELAMINE LLP

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |